Lutheran HS of San Antonio offers several opportunities for students to participate in robotics and related STEM activities.

|

Teams from the school have consistently performed well in both the FIRST Tech Challenge competitions and advanced to the regional level of competition the last several years with two appearances at the South Super Regional Championship and one appearance at the South World Championship.

In the 2015-2016 academic year, the campus added an under-water robotics event, MATE-ROV. In this program, students design, build, and program a remotely operated vehicle to pilot a course and run missions related to game theme that varies each season. Students spend time in the MAKE lab (robotics and engineering shop) during lunch, Friday afternoons, and after school one to two afternoons a week. |

|

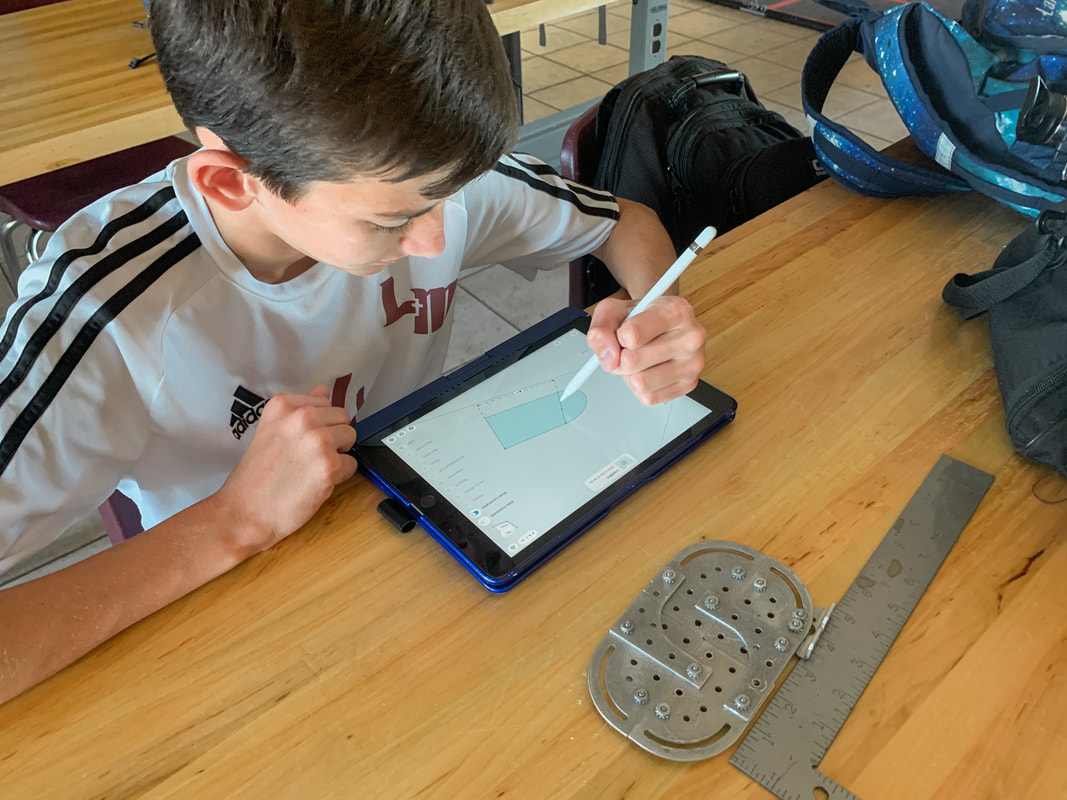

LHS students have opportunities to enroll in a sequence of two pre-engineering courses beginning as early as their sophomore year. We are one of less than ten schools in the area that offer both courses of Engineer Your World developed by the UT Austin Cockrell School of Engineering. These courses focus on engineering design processes and habits of mind. This curriculum employs project-based learning in a real-world and culturally relevant methodology. While the first year course hits many fields of engineering to include computer science and electronics, the second year course focuses exclusively on computer science and mechatronics via the python language and use of the Raspberry Pi microcomputer. This sequence of two pre-engineering courses is a major means by which LHS works to increase the diversity of students pursuing STEM degrees.

|

We have been very active in recent years in regards to adding to and improving the type of tools and equipment in the MAKE lab. We have expanded and relocated this area from a suite of two classrooms in the modular building to what was historically the administration building. The Make lab contains a classroom space for up to 24 students, a small computer lab for design and development work, a small dark room for development of Black and White prints, a large open space with workbenches for the multiple robotics team and a full FIRST Tech Challenge practice field (separate room for the MATE ROV competition team), a room for digital fabrication via a CO2 Laser cutter and multiple 3D printers, a metal machine shop and tool room, as well as a developing wood shop. The goal of this effort is to provide the equipment and tools necessary for students to design, build, program and create robots and a wide variety of DIY type projects. In additions to basic power tools such as two drill presses, bend grinder and compound miter saw, specialty machines include:

- 3 axis JET vertical Mill

- Bridgeport style Mill with Digital Read-Out

- Grizzly 2HP metal lathe with auto-feed options

- Grizzly 2HP wood lathe

- Vertical band saw

- Lulzbot TAZ6 3D printer with Dual Extrusion head, MOARstuder head, and standard head (

- Two 3DSsystems Ekocycle Cube 3d Printers.

- GlowForge 3D Laser cutter/engraver.